中国组织工程研究 ›› 2019, Vol. 23 ›› Issue (26): 4212-4216.doi: 10.3969/j.issn.2095-4344.1362

• 细胞外基质材料 extracellular matrix materials • 上一篇 下一篇

人工韧带聚对苯二甲酸乙二醇酯纤维的表面臭氧氧化

史丰田,张 梅,孙仕超,陈书香,李登云,孙雪莲

- 北京万洁天元医疗器械股份有限公司,北京市 102600

Ozone oxidation of the surface of artificial ligament material polyethylene terephthalate fiber

Shi Fengtian, Zhang Mei, Sun Shichao, Chen Shuxiang, Li Dengyun, Sun Xuelian

- Beijing Wanjie Medical Device Co., Ltd., Beijing 102600, China

摘要:

文章快速阅读:

.jpg)

文题释义:

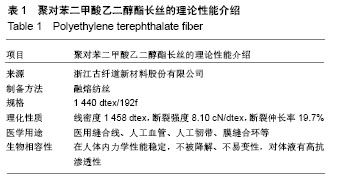

人工韧带材料:人工韧带主要用于膝关节韧带的重建与修复,其制作材料从早期的碳纤维、聚四氟乙烯、聚丙烯等,逐渐发展为目前以聚对苯二甲酸乙二醇酯为主。人工韧带材料具有来源广、强度大、恢复快、无供区并发症及疾病传播风险等优点,是缓解自体/异体移植物来源缺乏的重要途径。

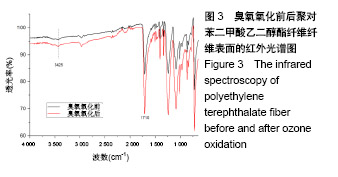

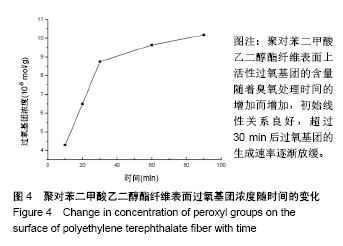

表面臭氧氧化:聚对苯二甲酸乙二醇酯分子结构对称、无强极性基团,故纤维表面的亲水性较差,提高纤维表面性能是发挥其功能的关键所在。在保证材料自身性能的前提下,通过臭氧氧化在纤维表面形成过氧基团,为后续接枝改性打下基础。臭氧氧化不需要化学试剂,无残余污染性副产物,需要的设备简单且操作容易。

背景:人工韧带材料聚对苯二甲酸乙二醇酯纤维具有较好的理化性能与力学性能,但其表面亲和性较差,不具备良好的细胞相容性,因此需要对材料表面进行改性处理。

目的:采用臭氧氧化法在聚对苯二甲酸乙二醇酯纤维表面生成活性位点,提高其细胞相容性。

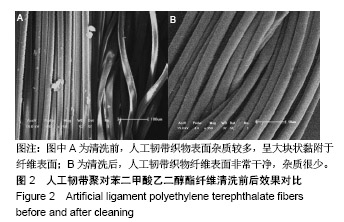

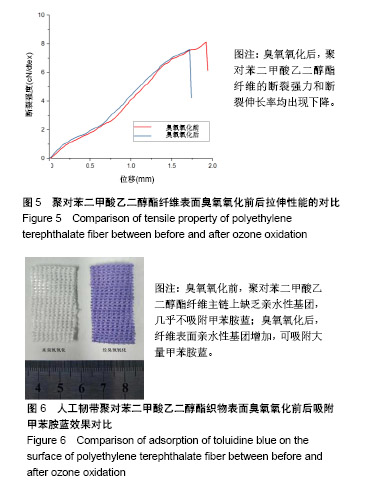

方法:取人工韧带聚对苯二甲酸乙二醇酯纤维经编坯布,裁剪成合适大小,放入蒸馏水中进行臭氧氧化处理:室温,氧气流量1 L/min,水中臭氧质量浓度10 mg/L,臭氧化时间30 min,表征臭氧氧化前后聚对苯二甲酸乙二醇酯纤维的表面形貌、力学性能与甲苯胺蓝吸附情况。

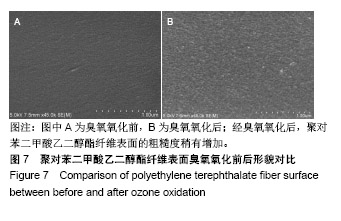

结果与结论:①扫描电镜显示臭氧氧化后,聚对苯二甲酸乙二醇酯纤维表面的粗糙度稍有增加,但无明显龟裂降解迹象;②臭氧氧化后,聚对苯二甲酸乙二醇酯纤维表面成功引入了过氧基团,过氧化物浓度10-5 mol/g数量级;③臭氧氧化后,聚对苯二甲酸乙二醇酯纤维表面未出现明显降解,力学性能保持良好,可满足人工韧带材料对聚对苯二甲酸乙二醇酯纤维拉伸性能的要求;④臭氧氧化前,聚对苯二甲酸乙二醇酯纤维主链上缺乏亲水性基团,几乎不吸附甲苯胺蓝;臭氧氧化后,纤维表面亲水性基团增加,可吸附大量甲苯胺蓝;⑤结果表明,臭氧氧化处理既能保证聚对苯二甲酸乙二醇酯纤维的力学性能又可在其表面引入足够的过氧基团。

中图分类号:

.jpg)